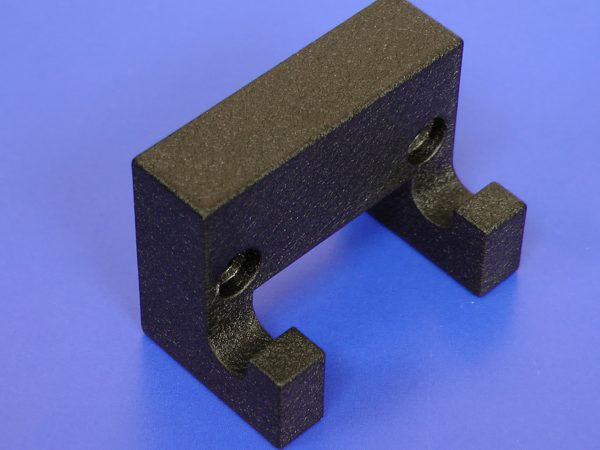

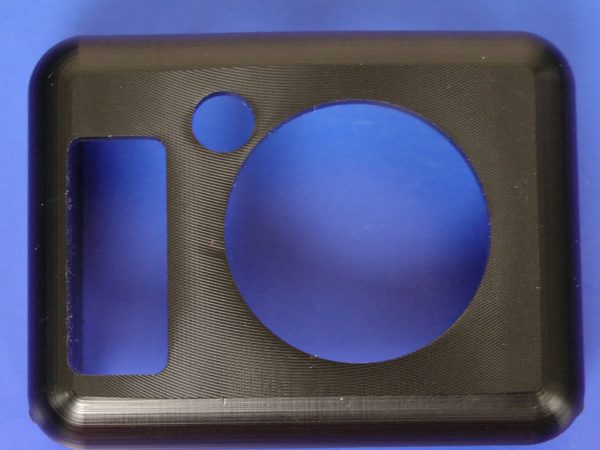

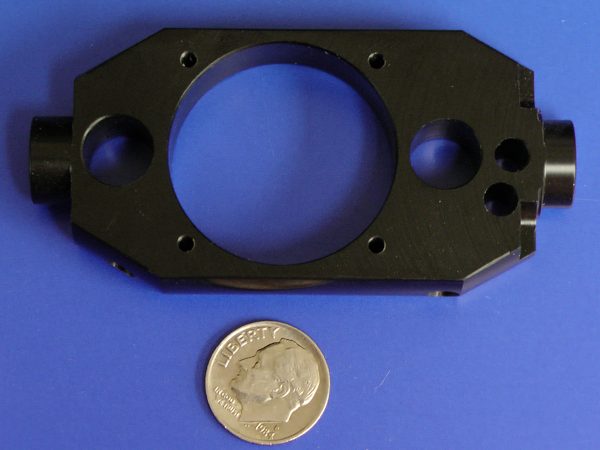

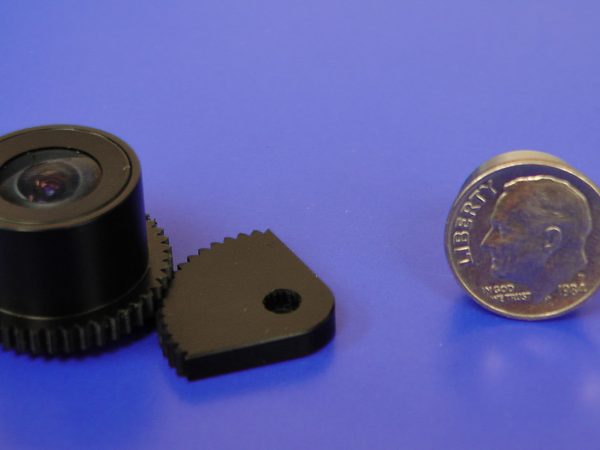

Do you need a single part made to repair a piece of equipment? Are you looking for a small number of pieces for prototypes? Do you need hundreds of pieces made for production? Northeast Precision Inc offers custom CNC machining services with products made to your exact specifications. Our experienced machinists and versatile machines are well equipped to tackle even the most complex precision machined metal components. From smaller volumes to high volumes, with our precision machinery, along with our in-house deburring and finishing capabilities, our team is ready to provide you the quality you deserve. Our machining capabilities include milling, turning, tumbling and finishing, and precision abrasive deburring.

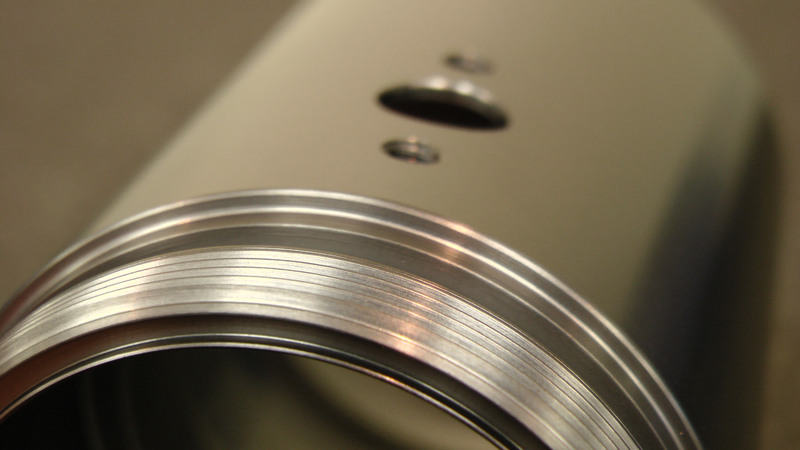

5 Axis CNC Turning

Turning is a machining process that uses single-point cutting tools to remove material from the rotating workpiece. The CNC turning machine feeds the cutting tool in a linear motion against the surface while it is rotating, removing material around the circumference until the desired diameter is achieved.

The ability to machine a workpiece to completion in a single setup not only adds to the precision achieved during machining but also reduces tooling costs and labor time. 5 axis turning machines eliminate several insufficiencies of traditional CNC machining techniques, including several setups, part transfers, part handling, and errors associated with human involvement.

Benefits:

• The workpieces can be completed at one machine with the finishing components having greater accuracy

• It can use shorter cutting tools producing higher cutting speeds and fewer vibrations for higher precision

• Ability to achieve outstanding surface finishes which improves the overall quality

• Single setup required for machining complex shapes which increases productivity

4 Axis CNC Milling

Milling is a machining process that uses rotating multi-point cutting tools to remove material from a workpiece. The CNC milling machine feeds the workpiece to the cutting tool in the same direction as the cutting tool’s rotation. 4 axis milling is useful when holes and cut-outs need to be made in the side of a piece or around a cylinder. The additional axis given on a 4 axis machine provides more detailed work that is faster and more accurate.